Subaru Build Update

Another update on the Subaru build. It's been slow going with Jenson still in the NICU. Nevertheless, Andy at Delaware Speed and Custom is cleaning up older projects in the shop and moving them around to fit the Subaru in the near future.

Lately what's hit my mind, is why IAG recommended the fuel pump will need to be "hard-wired." A lot of this may be just me rambling. But I'm going to try and leave everything I found on NASIOC. My understanding, which may be wrong is that ff the injectors are able to empty the fuel rail faster than the pump can refill, fuel pressure is going to drop. If anything that will just make the duty cycles on the injectors higher and probably make the condition worse. So a higher pressure from the pump is necessary, and thus:

We start at beginning from Phatbotti tuning:

But that's not all, because apart from the wiring needing to be upgraded the stock fuel pump controller is involved. And that means:

So, as long we're not running the stock Fuel Regulator (which we aren't), running a new pump 100% of the time might be the answer.

That being said, someone asked:

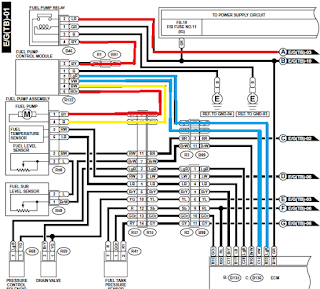

Some diagrams on wiring 100%:

So that's all the information I have on it right now. I'll let the internet know how the car ends up turning out.

Lately what's hit my mind, is why IAG recommended the fuel pump will need to be "hard-wired." A lot of this may be just me rambling. But I'm going to try and leave everything I found on NASIOC. My understanding, which may be wrong is that ff the injectors are able to empty the fuel rail faster than the pump can refill, fuel pressure is going to drop. If anything that will just make the duty cycles on the injectors higher and probably make the condition worse. So a higher pressure from the pump is necessary, and thus:

We start at beginning from Phatbotti tuning:

Turning up the fuel pressure on any in-tank pumps will be counterproductive and cause the fuel flow to decrease. If you want to turn up the fuel pressure you need to replace the stock fuel pump wiring with bigger gauge wire to allow the pump to receive more amps.

But that's not all, because apart from the wiring needing to be upgraded the stock fuel pump controller is involved. And that means:

The way it works is power supply voltage comes into the controller through the red power wire and goes out through the red wire to the pump. The ECU communicates with controller through the blue wires. Ground from fuel pump goes back to the controller through the yellow wire. The pump is controlled 33% 66% 100% through PWM signal, basically turning the pump on off at high speed to control the pumps output. Basically same way a boost control solenoid is controlled.

With all the wiring going through the controller it is going to limit amperage that can be carried on the circuit. If you want to hard wire the pump completely bypass the controller otherwise there is still going to be amp limitation to the system.

So, as long we're not running the stock Fuel Regulator (which we aren't), running a new pump 100% of the time might be the answer.

That being said, someone asked:

so is the stock fuel pump controller, ok with being wired to the walbro 400 with direct 14v?To which the answers were:

Totally, This is how my system is set up with the Walbro 400, an Aeromotive FPR and Junior made 535 WHP with my build and 1100 cc injectors at 80% idc. The fuel system had no trouble keeping up and Junior held back timing because of balance issues with the injectors, which we corrected now... Bottom line is this pump in the stock hangar, re-wired through the FPC with an aftermarket FPR can support pretty big power!And:

To answer your question, yes, the stock fuel pump controller will be fine if hardwired to it and then from it to the fuel pump. This will allow you to reap the benefits of having the hardwired fuel pump, but also to still allow the ecu to have control over it's duty cycle. There will be a very slight voltage drop across the controller, but it will be very small and won't really cause any issues or anything. Doing things this way is definitely better than the stock wiring. Obviously, the better solution would be to just hardwire the fuel pump for 100% operation, install an aftermarket fpr, and then you won't have anything to worry about.Before I go into what the DCCD pro people have come up with their own Fuel Pump Controller, let me just acknowledge a comment made about the pump being run all the time causing fuel warming up:

Not a big practical concern from my observations. I've tested it as my car is one of the ones with an in-tank fuel temp sensor that can be monitored. It has a surge tank, so the fuel is pumped by at least 2 A340 pumps running 100% all of the time, and sometimes by a 3rd (Hobbs switched activated at 25psi). I drove the car from full to empty and the fuel simply didn't appreciably heat up. And by then, it was ready to be replaced by a fresh tank of fuel anyways. Heat conducted from the engine to the fuel as it cycles the engine bay is probably a larger factor.So, it looks like if you want to keep a fuel pump controller within the system, DCCD pro has a product to fulfill that. Here some relevant info as to the why, first:

The issue with the stock FPC is that it is assumed it cannot handle the amps required by a walbro 465. At about 80 psi the pump draws about 20 amps. The Fuelpro can run up to 50 amps I believe. A stock pump only draws about 13.5 amps. These are all ballpark figures. I don't think you want to ground back to the stock FPC if you plan to run this pump. You will not get the flow that is needed by this pump.And this all seems to stem around the fact that the stock Fuel Pump Controller may not handle enough amperage for an aftermarket fuel pump's needs. Conversely, if you hardwire the pump, the argument is that having it run 100% (without a controller) will shorten its life span.

Glad to hear you guys find the FuelPro installation easy. It will maintain your pump longevity while not compromise on performance. We brought this product to market because we saw so many instances of bypassing the FPC causing pumps to fail prematurely.

The FuelPro FPC can operate at non standard (higher) voltages of up to 24 volts. The average current of 16.5 Amps needs to be maintained.My question about this is how this works in relation to the fuel pressure regulator (FPR) since the pressure needs to remain constant. I assume another reason for running the pump at 100% all the time is for ease of setting up the FPR.

Some diagrams on wiring 100%:

Comments